| A mountain of puer tea (not ours!) |

If you want to see the earlier steps of how the freshly picked leaves are produced into maocha, visit this earlier post on how puer is processed differently from other teas.

Maocha tends to be purchased in 10-15kg bags. For producers producing a tonne or two of xiaoshu cakes, the first step is to form a heap of blended maocha. This maocha is shovelled into cardboard boxes which are carried to 1 of 2 steaming rooms, and dumped into a smaller pile on the weighing table. Here the first technician (woman in the background) weighs out the tea into steamer tins with a perforated bottom, and places a neifei at the top, followed by a few more leaves to keep it in place. Each tin is then placed on top of the steamer. The steam rises through the perforations in the base of the tin, and the moistened tea leaves immediately begin to sink. Once sufficiently damp, the second technician (man in the foreground) pulls a cloth bag over top of the tin, and with a quick flip dumps the tea leaves out into the bag. The technician then uses his hands to compress the tea leaves inside the bag into a cake shape, before twirling and tucking the loose end into a knot at the center.

The next step is to place the bagged cake under a heavy stone press. A third technician adds his weight on top of the stone, and with a quick wobbly spin, gives the cake it's finished shape - a disc with slightly rounded edges. Don't you just love the motivational music in the video above? Methinks puer should be pressed to Chubby Checker "Let's do the twist"... or even better, Ludvig Van's 5th

| Steamed tea is pressed under a stone weight |

At first the cakes are left in the bag to cool & dry out. Once cool enough, the bag is removed, without affecting the integrity of the bing. The inside of the cake is still moist, and needs to given several hours to dry out naturally on a rack, preferably in the shade.

| Pressed puer cakes are placed in racks to dry |

|

| Puer cakes drying in a hongfang 烘房 |

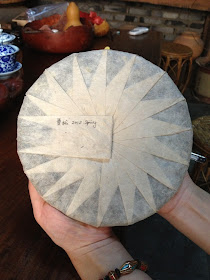

| Dried puer cakes ready for wrapping |

After the cakes are dry, they are hand wrapped in paper. This is fast & delicate handiwork and requires an eye for detail when folding. Perhaps this is why it's usually women who are the quickest and best wrappers. This young girl makes it look so easy!

This is the most perfectly wrapped cake I've seen so far.

Wrapping a stack of 7 cakes into 1 tong requires dextrous feet as well as hands. This requires more brute strength, and is usually done by men. I'm sure these guys work up some pretty nasty callouses. The biodegradable bamboo packaging is tough & beautiful. I dread the day when traditional bamboo wrappers are replaced with low cost cardboard bags (as Dayi has started using) or even worse, plastic.

Wrapping a stack of 7 cakes into 1 tong requires dextrous feet as well as hands. This requires more brute strength, and is usually done by men. I'm sure these guys work up some pretty nasty callouses. The biodegradable bamboo packaging is tough & beautiful. I dread the day when traditional bamboo wrappers are replaced with low cost cardboard bags (as Dayi has started using) or even worse, plastic.

| Wrapped tongs, ready to be boxed and shipped out |

The pictures shown in this post were taken at 2 different small to medium scale puer factories. In larger factories the pressing is done by machine or with stone weights on pulleys. The heavier stones used in this setup means no technician is required to stand on top. But without the human touch of the wobbly spin, this produces cakes with less rounded sides.

When it comes to puer, I think messing with tradition leads to ugly, more complicated solutions. We try to emphasize the human touch in our productions (see The Meaning of Hand Made).

To see puer production on a more intimate, smaller scale, check out this earlier post where we press cakes in Da Mengsong with Chong Kyongwon.

| Heavier stone presses on a pulley system |

To see puer production on a more intimate, smaller scale, check out this earlier post where we press cakes in Da Mengsong with Chong Kyongwon.

fascinating, thank you!

ReplyDelete